Not All Stainless Exhausts Are Created Equal: Why Material Matters

Think an exhaust is just a bunch of pipes welded together? Think again, design matters, fitment and clearance matter, but most importantly MATERIALS matter.

304, 321, 409, 201, we tend to rattle on about material grades when we talk about our product vs. other products on the market. But rarely do we dive in and discuss the details of what each of these materials are, why their use in exhaust design is important and why it's important to be able to trust that the company you spend your money with is doing what they say they are.

304, 321, 409, 201, we tend to rattle on about material grades when we talk about our product vs. other products on the market. But rarely do we dive in and discuss the details of what each of these materials are, why their use in exhaust design is important and why it's important to be able to trust that the company you spend your money with is doing what they say they are.

WHY STAINLESS?

Most people consider stainless steel to be an excellent use case for exhaust system development because of the apparent corrosion resistance effects, as well as the overall great look of the product. Whether it's standard mill finish, a #4 brushed finish like we use, or a full polish like you'll find in many overseas manufactured exhausts where low-cost manual labor is readily accessible, stainless does look excellent and carries high longevity under vehicles in most areas. In some areas, it's prone to corrosion due to the caustic reagents applied to roads (these days it seems to be a variety of salts, from sodium to magnesium chloride and a variety of acetates. All in all, fairly bad stuff that can quickly degrade metals, especially so for lesser grades of steel. So, if you live in an area like that, it's all the more reason to go after a quality material and even then, consider cleaning the undercarriage regularly.

WHAT IS STAINLESS STEEL, AND HOW DO DIFFERENT GRADES RANK?

Stainless Alloy Basics: Stainless steels are an alloy of Iron (Fe) that have specific alloying agents included in their makeup. Remember the periodic table? These are items like Carbon (C) and Manganese (Mn) for improving the hardness and other physical properties of the material, heavy metals like Nickel (N), Chromium (Cr), and Silicon (Si) to promote corrosion resistance, as well as Sulfur (S) and Phosphorus (P) to improve machinability. Depending on the grade of stainless steel, these alloying agents have different quantities, which in turn impacts the material cost. They also result in vastly different behaviors in the material - from resistance to thermal expansion over temperature change (that's what makes headers crack), to resistance to corrosives. So, let's take a look at the different grades, where they're good, and where they're lacking:

Stainless Alloy Basics: Stainless steels are an alloy of Iron (Fe) that have specific alloying agents included in their makeup. Remember the periodic table? These are items like Carbon (C) and Manganese (Mn) for improving the hardness and other physical properties of the material, heavy metals like Nickel (N), Chromium (Cr), and Silicon (Si) to promote corrosion resistance, as well as Sulfur (S) and Phosphorus (P) to improve machinability. Depending on the grade of stainless steel, these alloying agents have different quantities, which in turn impacts the material cost. They also result in vastly different behaviors in the material - from resistance to thermal expansion over temperature change (that's what makes headers crack), to resistance to corrosives. So, let's take a look at the different grades, where they're good, and where they're lacking:

304 Stainless Steel: While this isn't the most common grade for exhaust manufacturing, it's certainly up near the top of the list for best bang for the buck. T304 Stainless Steel does seem to be the most readily quoted grade of stainless referred to when a brand wants to hang its hat on quality. Here's the thing to remember, though, and the thing to ask: is the system all that grade of stainless? What about the perforated tubing inside the mufflers? What about the flanges (often times companies will run mild steel or lesser grade stainless flanges and then lightly plate them to match the look of the polished tubing on the exhaust). We have had a lot of Brand X exhaust systems pass through our shop and end up in the scrap bin after a customer rolls in for a fresh exhaust system, and we have seen it all.

409 Stainless Steel: A vast majority of factory and aftermarket stainless systems on the market are 400 series stainless, with 409 being the most common. Lacking in the Nickel and Chromium department vs. T304 stainless, 409 is less corrosion resistant than 304 both for the lack of those alloying agents as well as for lacking the structural effect they have.

See, in 304 stainless, the nickel and chromium levels not only improve the material itself, but they also change the structure / lattice of the material and allow the molecular structure of that material to evenly distribute the chromium and nickel throughout the material. As nickel levels drop, the chromium is less evenly dispersed in the lattice, resulting in more potential for corrosion and stress cracking. Even then, 409 series stainless isn't terrible; it's what many factory exhaust systems are made from and it isn't the thing you have to really worry about when purchasing an exhaust, at least you'll know what you're getting.

See, in 304 stainless, the nickel and chromium levels not only improve the material itself, but they also change the structure / lattice of the material and allow the molecular structure of that material to evenly distribute the chromium and nickel throughout the material. As nickel levels drop, the chromium is less evenly dispersed in the lattice, resulting in more potential for corrosion and stress cracking. Even then, 409 series stainless isn't terrible; it's what many factory exhaust systems are made from and it isn't the thing you have to really worry about when purchasing an exhaust, at least you'll know what you're getting.

And how do you know? Well, pretty easy, while 304 stainless will have little to no evidence of magnetism, 409 does. A good neodymium magnet will stick to 409 while it'll barely attract toward a straight length of 304 (bends are another story, we can discuss the science behind that later). The shortcomings of 409 are simple: It tends to rust on the surface over time even if it's not exposed to corrosive agents. The good news is that it's usually just cosmetic - and doesn't have high of a potential to fail or rot out as mild steel or other suboptimal grades of stainless will.

Lets talk about one of them:

200 Series Stainless: Yeah... if 304 is the good, 409 is the bad, 200 series stainless is most certainly the UGLY. It's the material nobody ever told you to watch out for, because a lot of companies and even some material manufacturers don't even know it's floating around in circulation.

So what is it? Well, it's fake 300 series stainless. It's literally a grade of stainless steel that was engineered to behave like 304, in that it is non-magnetic. But it bends differently, it corrodes quickly and without abandon, and it has very little material strength in comparison to the material it is mean to mimic. So how is it done? On the sly, that's how. The mill substitutes the expensive and corrosion resistant Nickel alloy for Manganese. The result is a more brittle product that lacks the uniformity of distribution of the corrosion inhibitors like Chromium. Put it out in the elements and it's not long before it begins to rust, and it doesn't stop.

And this is where shopping with a manufacturer that is known for its quality is a critical component in making the decision on who you should spend your money with.

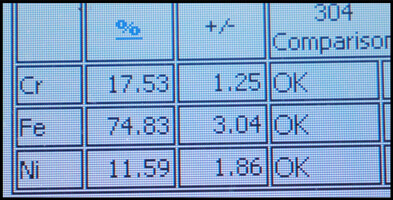

Nameless Performance lot tests every single batch of material and discrete components that come in the door for every stainless product we make. Using a state-of-the-art XRF analyzer we get a full breakdown of material properties for each shipment to ensure that the certificates that are sent with the materials match the material we have received. This is certainly not the industry standard in our world of aftermarket automotive, but the potential for material fraud is high enough to demand that any manufacturer who is worth their salt (pun intended) be equipped to provide the level of quality assurance to their customers that we do for you.

Lets get back to the good...

So, let's get past the shitty details of material science and talk about the really cool stuff. Like 321 Stainless and Docol R8, materials that perform flawlessly at specific tasks where spending a little extra money can go a long way in assuring that you only have to spend the money once.

321 Stainless Steel: If you're buying a header or turbo exhaust manifold, this is absolutely what you're looking for - cost is significantly higher than 304 stainless, but when temperatures get astronomically high, 321 features some extra alloying agents like Titanium to keep the coefficient of thermal expansion to a minimum. What's that? Well, that's when something gets hot and wants to expand. Weld 28 of those somethings together and you'll either need cross-sectional area (heavy tubing) or flawlessly engineered parts to keep the components from trying to tear each other's arms off while you're doing pulls or banging off rev limiter at your local drift track.

Docol R8: While not a technically stainless steel, Docol R8 deserves a shoutout in the world of high-performance tubing. This Swedish-made, advanced high-strength steel (AHSS) is prized for its exceptional tensile strength, lightweight properties, and superior weldability. While it doesn't have the corrosion resistance of 304 or 321 stainless, Docol R8 is occasionally used in motorsport exhaust systems where strength-to-weight ratio is critical, and vehicles are maintained regularly. Typically, it sees more action in roll cages, suspension components, and structural applications. If you're chasing every ounce of weight savings and maximum rigidity and you're willing to protect against corrosion, Docol R8 delivers.

Final Thoughts:

Final Thoughts:

At Nameless Performance, every single exhaust system we build is crafted from true 304 stainless steel. No compromises and no shortcuts here. If you're shopping for an aftermarket exhaust and the manufacturer doesn't specifically state it's made from 304, you can bet it's almost certainly a lower-grade 200 or 400 series stainless designed to save them money; not to deliver long-term performance for you. Don't fall for polished looks hiding subpar materials.

That said, even the best stainless steels aren't invincible. Road salts, deicers, and other corrosive agents will eventually attack any material, 304 included. So, if you live in an area where winter road treatments are common, it's critical to wash your undercarriage regularly to maximize the lifespan of your exhaust and consider a quality metal polish to keep the shine on your tips. Choose wisely, maintain it right, and your system will last as long as your love for the drive.

Recent Posts

-

Not All Stainless Exhausts Are Created Equal: Why Material Matters

Think an exhaust is just a bunch of pipes welded together? Think again, design matters, fitment and …Feb 09, 2026 -

A Must-Have Oil Upgrade for Subaru FA & FB Engine Longevity

Why Subaru FA & FB Engines Suffer From Oil Drain-Back If you've owned your Subaru for a while, you m …Nov 25, 2025 -

Calculating The Perfect Subaru No Drone Exhaust Note: Dual Chamber Exhaust Systems

The community has spoken and we are listening. It has been a great start to the year, we have made a …May 15, 2020