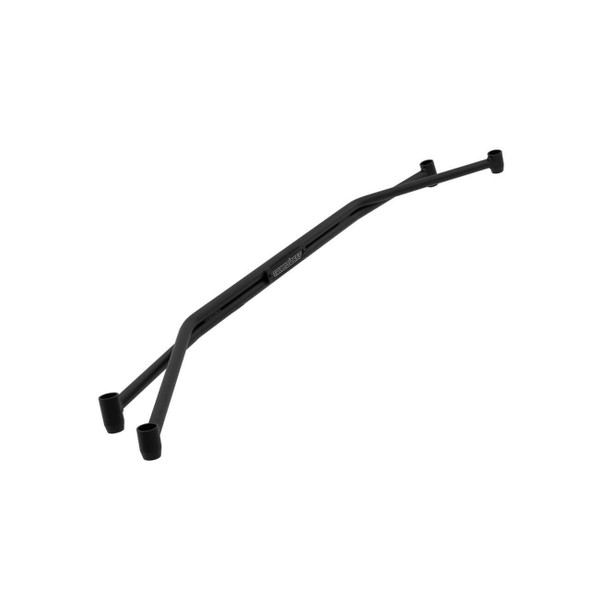

Wave Spring Bypass Valve - 2002-2021 STi / 2002-2007 WRX / 2004-2007 Forester XT

- SKU:

- SUBPV02STI-02WRX-04FXT

- MPN:

- SUBPV02STI-02WRX-04FXT

- Condition:

- New

- Shipping:

- Calculated at Checkout

Description

**New for the 2002-2021 Subaru STi, 2002-2007 WRX and 2002-2007 Forester XT.**

We are very excited to announce some updates to this product line. A few years ago we picked up a new Haas VF4-SS CNC mill, optioned up with a fourth axis. It was a time saver for loading and running operations on our handbrakes and other products that allowed our operators to work on fabrication while the machine made growling noises and filled trash cans with chips. But we finally had an incredible opportunity to use the fourth axis to its fullest with this new monobloc design for the STi and GD WRX/FXT bypass valve. Starting from a massive block of 6061-T6 aluminum, this entire bypass valve body is cut in a single work holding operation, with the machine cutting on all sides of the outlet tube and profiling the inside of the tube using long reach tooling. We absolutely did not do this because we had to. We did it because we could.

Function:

The most important feature of a recirculating bypass valve (Recirculation Valve, BPV, BOV) on your Subaru is to evacuate the pressure out of the charge circuit when the throttle is closed. This prevents a surge of boost from hitting the throttle and then reflecting back toward the compressor wheel where it can slow or even stop the movement of the compressor wheel and corresponding turbine wheel. Ideally, the function of a bypass valve is to open this circuit and dump that pressure and drag on the turbocharger compressor wheel out to the un-pressurized intake downstream of the Mass Airflow Sensor. This ensures that the vehicle still has the air accounted for to avoid afterfire and extreme rich running conditions on transition from one gear to the next. The faster the valve can open and the more the valve can flow, the better it is at evacuating that drag on the turbocharger. Unfortunately, with most diaphragm based designs, that comes at a trade off. You either have a valve that acts slowly (opening too slow resulting in some really interesting sounds as it opens) or a valve that can open quickly but has a small cross-sectional area of flow in order to allow it to act quickly but to hold boost when you want it to remain closed. Unfortunately the factory design on the STi is the former, with a large valve face and slow acting diaphragm. Equally troubling, the factory large surface area valve in combination with said diaphragm is known to be easily forced open under higher than stock boost pressures resulting in boost leaks which can often cause issues with tuning as boost targets are often moving targets.

The Nameless Performance Wave Spring Bypass Valve is designed to hold far higher pressures than the factory unit, ensuring that no loss of boost charge out the bypass valve when you have the throttle open. This valve design also opens incredibly fast, resulting in a charge circuit purges quickly, without restriction when the throttle shuts. The result is quicker re-spool of the turbocharger after shifts and deceleration events, as well as a more consistent platform for tuning by preventing leaks out the bypass valve which are often a moving target and result in significantly different peak boost numbers as the factory valve intermittently leaks. If you're already running a pro-tune with a reliable valve, this valve should be a direct replacement, but if you are replacing a leaking factory valve with our valve, it is recommended you consult your tuner for advise prior to running the updated valve in the case that you may be sealing up a leak and dealing with the resultant increase in boost pressure.

We have run these successfully with and without tuning, the only need for a re-tune is if you've got the vehicle tuned with an already leaking valve and are replacing it with one that does not leak.

Design:

- Piston and wave spring design has no rubber diaphragm to fail or leak boost. By utilizing a wave spring as the pre-load spring on the piston, we are able to reduce overall package sizing by getting an equivalent seat pressure with a flatter overall compressed design. Likewise, the piston design affords us a much less threshold for leaking or rupturing of the pressure retaining diaphragm that is featured in many of the valves sold by our competition.

- Stainless hardware throughout, clock able cnc machined banjo fitting, billet piston.

- 100% Machined and Assembled In-House at Nameless Performance in Woodland, Washington.

- Patented internal design.